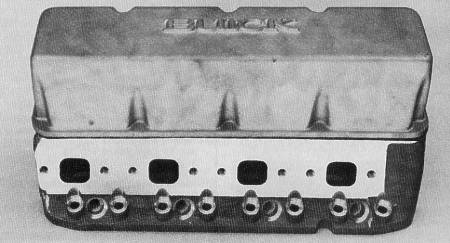

Dart's unique new cylinder head for the small-block Chevy has the ports and combustion chamber of a Buick Stage II V6. And a Buick part number.

WITH AT LEAST EIGHT different companies producing aluminum cylinder heads for the small-block Chevy, it would seem that the last thing the world needs is another small-block head. In fact, that is precisely what it needs. While each of the aftermarket heads offers specific advantages over other designs, there is a decided similarity between small-block race heads and their stock production counterparts. And therein lies the problem.

Even the latest and greatest edition race head is clearly a direct descendant of the original design which was conceived over 30 years ago, and engineered to accommodate the requirements of a mild-mannered, 265-cubic-inch production engine. Over the years, port size and shape, valve diameter, and combustion chamber volume have been altered to optimize performance characteristics for specific applications. Testimony to the genius of the original design can be seen in the fact that with these relatively minor changes, Chevy heads have built an enviable record in virtually all forms of motorsports.

Unfortunately, Father Time and Mother Technology have caught up with the traditional small-block Chevrolet cylinder head. The basic casting has become the limiting factor as all-aluminum race heads are stretched almost to their limit when prepared for circle track racing. Significant improvements in both quantity and quality of air flow will come only through major alterations in port geometry, valve angle, and combustion chamber configuration.

Although he didn't state it quite so eloquently, Dick Maskin of Dart Machinery reached that very conclusion some time ago. Dart had already achieved considerable success with its aluminum heads for both big- and small-block Chevrolets, but Maskin was convinced that something else was needed. He considered adapting the Cleveland Ford design, but found that concept to be impractical. Concurrently, Bobby Allison was pushing for a new cylinder head design that would allow Chevy-based Winston Cup engines to reach horsepower parity with the Fords. Having spent quite a few laps behind the wheel of a Buick V6 Grand National Sportsman car, Allison was well aware of the Buick's awe-inspiring horse-power-per-cubic-inch achievement. Incorporation of the Buick Stage II design in a small-block Chevrolet head seemed to be a natural.

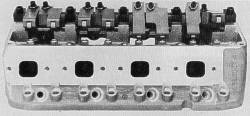

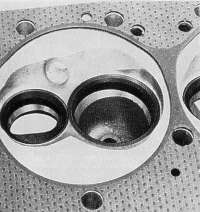

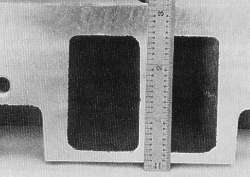

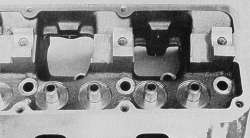

|

| Note the position of the valves in this standard Chevrolet head. Also note that the standard Chevrolet combustion chamber is considerably larger than the one in the Dart/Buick head. |

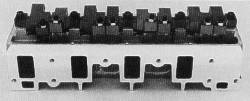

With that in mind, and with the cooperation of Buick Special Products Engineering, Gary St. Denis and Gary Custer of Dart set about the task of working up a small-block Chevrolet head that incorporated the port configuration, valve angle, and combustion chamber shape of the Buick V6. Judging from initial testing, that cylinder head, which bears the Buick name and a genuine Buick part number, threatens to make heads of the standard Chevrolet configuration obsolete for maximum horsepower efforts.

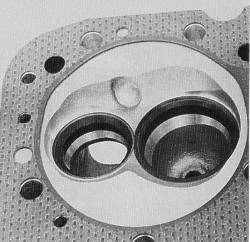

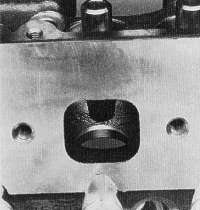

Port volume and valve size are typically the focal points when a cylinder head is evaluated for its horsepower producing potential. While these considerations are certainly important, Maskin is quick to point out that the Buick design offers other significant advantages. "On the Buick head, if you draw a line from the center of the intake valve to the center of the exhaust valve, that line is almost dead on the cylinder centerline. That means the valves are at the widest part of the bore, so shrouding by the cylinder wall is a lot less than with a standard Chevy head. The

valves are also equally unshrouded on each side. With 2.100-inch intake and 1.625-inch exhaust valves and a 4.000-inch bore, there's still an 1/8-inch bore clearance on each side. You just can't get that kind of clearance with the old-style Chevy head."

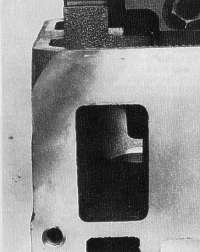

Another important, yet subtle difference between the Buick and Chevrolet designs, is the distance from the port floor to the deck. In traditional Chevy heads, the floor is virtually right down on the deck. Incoming air-fuel mixtures must climb upward before turning down over the short turn radius. In contrast, the floor of the Buick port is approxi-mately 1/2-inch higher so the intake charge travels a straight path from the manifold/head junction to the short turn radius. Combined with a port that is generously proportioned, the increased floor height improves intake flow char-acteristics and horsepower potential.

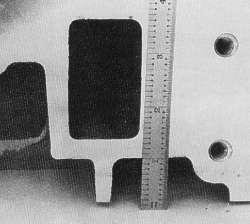

Intake port volume is nominally rated at 235cc. But direct comparisons can't be made with standard Chevy head port volumes because the Buick port is longer and higher. According to Maskin, the 235cc specification compares roughly with 210cc in a standard head, but there is considerable room for expansion.

Gary St. Denis purposely kept the ports on the small side. He states, "You can't make everybody happy, so we decided to start with relatively small ports because it's easier to remove material than to add it. These heads definitely need to be ported before they're put on a race engine. After we get some feed-back from engine builders, and find out what they really want, we'll alter the castings to reduce the amount of grinding required. We just didn't want to second-guess the engine builders."

Another notable difference between Chevy and Buick cylinder heads is the valve angle. In the Buick design, the valves are pitched at a 10° angle from the horizontal plane; the Chevy design utilizes a 23° valve angle. As a consequence, the Buick chamber is flatter, thereby promoting improved combustion efficiency. At 43cc, the chamber is also smaller, allowing for compression ratios (with a displacement of 350 cubic inches) approaching 13:1 to be acheived with flat-top pistons.

Although the Dart/Buick head

may be revolutionary in terms of the small-block Chevy, parts such as valves and rocker arms are readily available. The heads will accept Buick Stage II V6 valves and, of course, a wide variety of retainers, locks, and seals are available. At present, three rocker arm systems are being manufactured. T & D Machine offers a single-shaft rocker assembly system while Jesel and Zorian offer systems employing four shafts per head. (Two rockers are mounted on each shaft.) The Jesel system incorporates aluminum rocker arms while Zorian's employs stainless steel.

On paper, the Dart/Buick head offers considerably higher flow potential than its rivals. But impressive specifications don't win races. The vital question is whether these cylinder heads will fulfill their promise in terms of real-world performance. St. Denis feels confident that they will, saying, "I don't like to quote flow figures because when you do, everybody calls you a liar. But on our flow bench, on the 400-CFM scale, we've seen readings on the intake port of 85-87%. That's about 8-10% better than any other small-block head we've tested."

To complement the heads, Dart is also producing valve covers and a single four-barrel intake manifold. Production versions of both should now be available and a fuel-injection manifold is slated for the near future.

As this is written, the only dyno figures available are from an early effort by Carl Wegner, who used a pair of proto-type Dart/Buick heads on an engine he built for Bobby Allison. According to Maskin, "Ruggles is getting about 1.87 horsepower-per-cubic-inch with his 274-inch Stage II V6s. With 45-cubic-inch cylinders, which is the same size as the 274-inch V6, the first V8 Chevy test engine put out 660 horsepower. That figures out to roughly the same horsepow-er-per-cubic-inch ratio as the Buick V6, so we're right on target.

Port volume and valve size are typically the focal points when a cylinder head is evaluated for its horsepower producing potential. While these considerations are certainly important, Maskin is quick to point out that the Buick design offers other significant advantages. "On the Buick head, if you draw a line from the center of the intake valve to the center of the exhaust valve, that line is almost dead on the cylinder centerline. That means the valves are at the widest part of the bore, so shrouding by the cylinder wall is a lot less than with a standard Chevy head. The valves are also equally unshrouded on each side. With 2.100-inch intake and 1.625-inch exhaust valves and a 4.000-inch bore, there's still an 1/8-inch bore clearance on each side. You just can't get that kind of clearance with the old-style Chevy head."

Another important, yet subtle difference between the Buick and Chevrolet designs, is the distance from the port floor to the deck. In traditional Chevy heads, the floor is virtually right down on the deck. Incoming air-fuel mixtures must climb upward before turning down over the short turn radius. In contrast, the floor of the Buick port is approxi-mately 1/2-inch higher so the intake charge travels a straight path from the manifold/head junction to the short turn radius. Combined with a port that is generously proportioned, the increased floor height improves intake flow char-acteristics and horsepower potential.

Intake port volume is nominally rated at 235cc. But direct comparisons can't be made with standard Chevy head port volumes because the Buick port is longer and higher. According to Maskin, the 235cc specification compares roughly with 210cc in a standard head, but there is considerable room for expansion.

Gary St. Denis purposely kept the ports on the small side. He states, "You can't make everybody happy, so we decided to start with relatively small ports because it's easier to remove material than to add it. These heads definitely need to be ported before they're put on a race engine. After we get some feed-back from engine builders, and find out what they really want, we'll alter the castings to reduce the amount of grinding

required. We just didn't want to second-guess the engine builders."

Another notable difference between Chevy and Buick cylinder heads is the valve angle. In the Buick design, the valves are pitched at a 10° angle from the horizontal plane; the Chevy design utilizes a 23° valve angle. As a consequence, the Buick chamber is flatter, thereby promoting improved combustion efficiency. At 43cc, the chamber is also smaller, allowing for compression ratios (with a displacement of 350 cubic inches) approaching 13:1 to be acheived with flat-top pistons.

Although the Dart/Buick head may be revolutionary in terms of the small-block Chevy, parts such as valves and rocker arms are readily available. The heads will accept Buick Stage II V6 valves and, of course, a wide variety of retainers, locks, and seals are available. At present, three rocker arm systems are being manufactured. T & D Machine offers a single-shaft rocker assembly system while Jesel and Zorian offer systems employing four shafts per head. (Two rockers are mounted on each shaft.) The Jesel system incorporates aluminum rocker arms while Zorian's employs stainless steel.

On paper, the Dart/Buick head offers considerably higher flow potential than its rivals. But impressive specifications don't win races. The vital question is whether these cylinder heads will fulfill their promise in terms of real-world performance. St. Denis feels confident that they will, saying, "I don't like to quote flow figures because when you do, everybody calls you a liar. But on our flow bench, on the 400-CFM scale, we've seen readings on the intake port of 85-87%. That's about 8-10% better than any other small-block head we've tested."

To complement the heads, Dart is also producing valve covers and a single four-barrel intake manifold. Production versions of both should now be available and a fuel-injection manifold is slated for the near future.

As this is written, the only dyno figures available are from an early effort by Carl Wegner, who used a pair of proto-type Dart/Buick heads on an engine he built for Bobby Allison.

According to Maskin, "Ruggles is getting about 1.87 horsepower-per-cubic-inch with his 274-inch Stage II V6s. With 45-cubic-inch cylinders, which is the same size as the 274-inch V6, the first V8 Chevy test engine put out 660 horsepower. That figures out to roughly the same horsepow-er-per-cubic-inch ratio as the Buick V6, so we're right on target.

NORMAL-STYLE 350 CHEVY V8 heads haven't changed their port layout or configuration since 1955 (31 years). The following are some design concepts incorporated in the Dart head that we feel are beneficial.

The valve angle has been changed to provide for a flatter chamber. The top ring may be run higher because there is less valve notch interference, which also allows for the use of larger valves. With the flatter chamber at about 48cc, you can achieve 12.5:1 compression ratio with a flat-top piston. This provides a potential horsepower increase because with a flat-top piston, the air flow and flame travel aren't hindered by the dome. Also, a piston without a dome is lighter, therefore creating a lighter bal-ance assembly and effectively helping the engine respond to accelerator applications sooner.

Intake ports are spread apart like a big-block Chevy, which allows for extensive reworking of intake and exhaust ports. The Dart heads have improved intake port volume, which is good for both large-displacement and 9:l-compression engines- No two exhaust valves are positioned together, therefore helping to eliminate the extremely hot area in the center of the head and in turn that lessens the chance of burning the head and header gaskets. The valve covers have more hold-down bolts to help eliminate oil leaks and hold gaskets in position better. There is more distance on the Dart head between header flange and valve cover gaskets which helps eliminate unwanted distortion of valve cover gaskets. The intake manifold is about 3 inches taller than normal.

The following are some general specifications that should be known. The overall external dimensions of the engine will be greater with the Dart heads in place and it will be approximately 2 to 3 inches taller. Special intake and valve cover gaskets are available, but header gaskets are still in the develop-ment stage at this writing. Normal Che-vy racing valvetrain parts will not fit; you must use Buick V6 parts or after-market pieces. The roller lifters must be of the offset pushrod style, used in every hole in order to clear the intake port. Pistons and camshaft must be specially made to accommodate the intake, ex-haust, intake, exhaust valve layout of the cylinder head. Valve sizes are 2.100-inch and 1.625-inch with special-length stems. Special-length head studs must also be used. The heads use an integral valve guide. In general, the castings as delivered are very well made and require minimum machine work.

-RAY BAKER