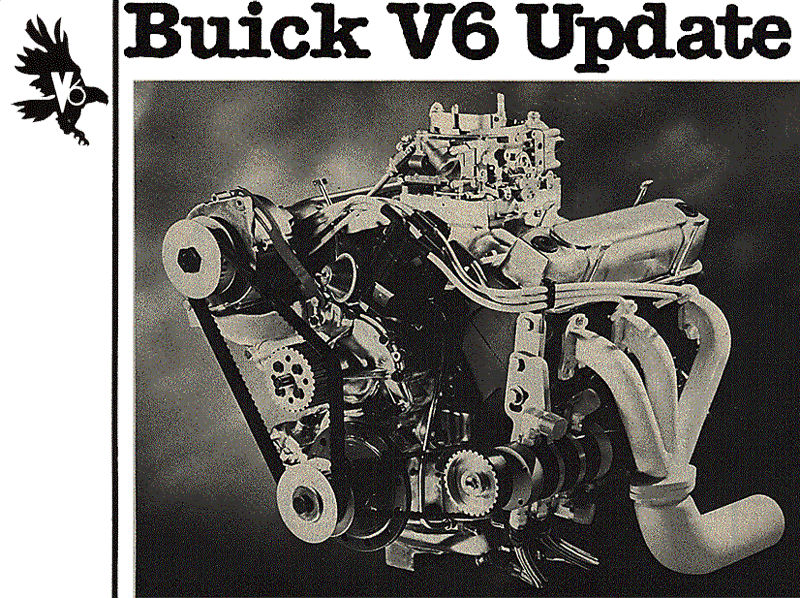

Just a little over two years ago, we raised a few eyebrows by predicting that the V6 engine would eventually replace the V8 as the standard of performance in enthusiast vehicles. Obviously, such a transition isn't going to take place overnight, but it is well under way; and only a fool would be blind to the inevitable shift toward smaller and lighter engines coming from Detroit, as well as the gradual phasing out of the V8. In case you haven't noticed, big-block V8s left the production scene several years ago, and displacements of 350 cubic inches or larger are only offered as options in a handful of 198O cars. By 1985, we will be faced with new car choices powered almost exclusively by four and six cylinder engines.

Does this mean an end to performance? Hardly. Extensive performance development work has already been done on the first of the new generation of potential performers the Buick V6. Power levels per cubic inch for

modified Buick V6s are now close to those of the best small-block V8s, and the specialty equipment industry has been quick to appreciate this new trend in engines, responding with a virtual avalanche of heavy-duty performance parts.

Much of the rapid acceptance of the V6 must be directly attributed to Buick's Special Product Engineering for their insight into the enthusiast's continued interest in performance in these days of reduced displacements and ever-increasing gasoline prices. Buick has responded by taking the initiative in developing heavy-duty service components for their 3.8-liter (231-cubic-inch) and 4.1-liter (252-cubic-inch) V6s. And to keep this program directly on course, Buick has enlisted the analytical and development talents of one of America's greatest engine builders, Smokey Yunick.

If you were with us back in January of '78 when we kicked off our V6 coverage, you'll remember that we out-lined

Smokey's appraisal of the Buick V6 from a performance standpoint, and followed along with his initial investigation of the odd-fire 90-degree Buick V6, which led to a power output of 355 hp from the 231-cubic-incher. Now, a little more than two years later, Smokey has expanded his development work to include the '78 and newer even-fire V6s, and power levels have been increased to nearly 375 hp for that same 231-cubic-inch displacement and it's all been done with parts that are readily obtainable to anyone who wants to duplicate his efforts.

This last statement might not seem too important, but two years ago many of the performance pieces for the Buick V6 required extensive modification (such as the cylinder heads) or complete fabrication (such as the intake manifold, headers and oiling system). Today, the amount of performance equipment available for the Buick V6 is staggering: All the major manifold manufacturers have aluminum 4-barrel manifolds available or under development for the V6; headers are offered in several different configurations; electronic ignitions and magnetos are available, with or with-out mechanical tach drives; hydraulic, solid,

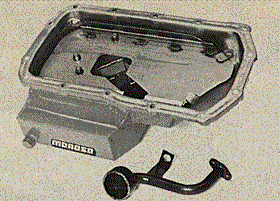

mushroom and even roller camshafts are now available, along with needle-bearing, roller-tip, adjustable aluminum rocker arms; there are aluminum valve covers, special oil pans, dry-sump oiling systems, block girdles, aluminum flywheels, special connecting rods and pistons, specialty piston

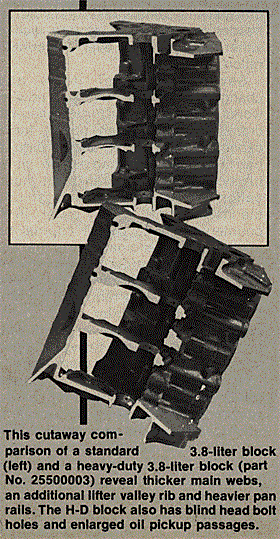

rings and bearings, a wide assortment of gaskets; and there's even a completely redesigned supercharger, drive and manifold for the Buick V6. The factory is doing its part too, with heavy-duty blocks, heavy-duty cylinder heads, rolled-fillet crankshafts, heavy-duty fuel pumps with special high-compression forged pistons,

heavy-duty connecting rods and aluminum cylinder heads just around the corner. But enough of what's happening on the parts scene. Let's take a look at what Smokey has been doing.

Smokey has shifted his efforts exclusively to modification of the even-fire Buick V6 produced since 1978. There doesn't seem to be any real power difference between the odd-fire and even-fire configurations, nor is there much difference in vibration after both versions are fully modified; but the majority of aftermarket parts are being produced for the later even-fire engines, so that seems to be the way to go. The even-fire concept, which utilizes a 30-degree offset on the connecting rod journals of the crankshaft to permit firing impulses evenly spaced 120 degrees apart, is also more compatible with electronic ignition systems and magnetos. Surprisingly, it turns

out that the same intake manifold and header designs work equally well on either the odd-fire or even-fire configuration.

Several important items have changed since '78. Smokey now re-works the production turbo rolled-fillet crankshaft rather than opting for an expensive billet crank, and to date, he hasn't had a crankshaft failure. In actuality, much of the crankshaft modification Smokey does, which includes the installation of "heavy metal" in the counterweights to permit internal balancing of the engine, is for the convenience of changing flywheels and dyno-testing rather than for durability.

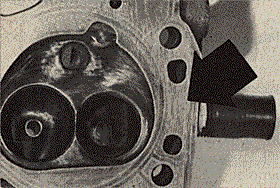

Another area that requires less modification is the cylinder head porting, since the '79 and newer production heads, as well as the heavy-duty service cylinder heads, now feature the latest raised-port design for increased flow. The shaft-mounted rocker arm system is also retained nowadays, instead of a conversion to individual stud mounted rockers, as was done in '78. The availability of adjustable needle-bearing aluminum rocker arms from Crane has helped make the stock system workable.

These are the highlights of equipment changes. Better cams and the use of magneto ignition have helped push the current power level to nearly 375 hp from a normally aspirated 231-cubic-inch V6 with dependability. But Smokey has also put his talents to work building a blown, 252-cubic-incher for HOT ROD, as detailed in the accompanying feature. Follow along as Smokey reveals some of the tricks that make his Buick V6 engines powerful, dependable and, in this case, very practical too.