Suppose you wanted to build an ideal hot rod engine for the '8Os. It would have to be contemporary, light-weight, compact in size, powerful (about 300 hp), yet well-mannered on the street, economical, reliable and, last but not least, a real head-turner. The answer to all these requirements is surprisingly simple.

We are entering the age of the V6 engine, which is perfect in terms of being current, lightweight, compact and economical, so a V6 was chosen over a V8. To achieve the power and torque desirable in an enthusiast engine, the new Buick 4.1-liter (252-cubic-inch) V6 - which is the largest American V6 engine in production, thus making it the logical starting point - was selected.

The Buick V6 was also a good choice in terms of economy - have you noticed how many of the General Motors new car advertisements refer to EPA gas mileage ratings for models equipped with the "corporate" V6 engine? In the majority of cases, the corporate V6 engine is the Buick V6.

Once the basic engine had been selected, the requirements of power, smooth operation and cosmetic appeal still needed refinement, and nothing meets all these requirements better than a fully polished Roots-type blower. By no small coincidence, Dyer's Machine Service, Inc. (7665 W. 63rd St., Summit, IL 60501), has just announced a new custom-made super-charger for the Buick V6. Gary Dyer has designed his own downsized blower, drive and blower manifold for the Buick V6, which is properly sized and matched to the smaller V6 dimensions.

With the basic engine type and configuration determined, all we needed was somebody with experience to assemble such an engine and test it for us. Again, the choice was obvious. If you're going to build a Buick V6, why not go to the acknowledged master, Smokey Yunick!

Smokey began this project with a prototype heavy-duty 4.1-liter block. Buick will soon offer the heavy-duty 4.1-liter block, in addition to their heavy-duty 3.8-liter block. The only basic difference between the 3.8 and 4.1-liter engines is the bore size. The 3.8-liter uses a bore of 3.800 inches (that's easy to remember), and the 4.1 - liter

uses a bore of 3.975 inches. The stroke is 3.400 inches for both displacements and the crankshafts interchange. The only other difference in the 4.1-liter block is that it has four additional water jacket core holes in each deck, which, as you will see later, caused Smokey some problems during engine assembly.

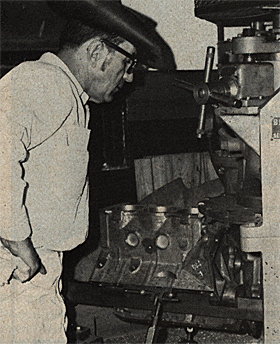

The block was fully deburred and align-honed. The oiling system was re-worked to enlarge the oil pickup gallery to a full 5/8-inch diameter, and provisions were made to smooth oil flow from the oil pump to the main oil galleries. Additionally, Smokey modified the heavy-duty block with external oil lines that feed oil directly to the second and third main bearings.

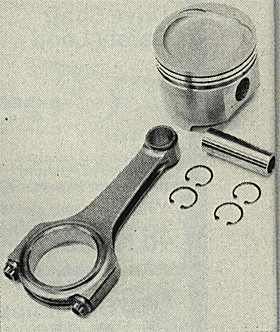

The third main bearing is the thrust bearing in the Buick V6, so its oil supply is critical at high crankshaft speeds. With the addition of the side oiling lines, the internal oiling system is able to supply plenty of oil to the rear main bearing. This oiling modification has virtually eliminated any bearing problems In the Buick V6. The last operation to the block was to weld the long water passage slot (at the rear of each deck) partially closed, thus giving extra support to the rear cylinder wall and improving head sealing. The corresponding passages in the cylinder heads were similarly closed. The block decks were then milled to square them with the crankshaft centerline, and the cylinder bores were sized and honed to a very smooth finish. The crankshaft is a production rolled-fillet turbo crank. It has been completely deburred and five "bullets" of "heavy metal" have been installed in each of the two end counterweights to permit internal balancing (all production Buick V6 engines are externally balanced). Clevite 77 bearings are used, with main and rod clearance set at .0025 - inch. Since Buick's heavy - duty connecting rod was not yet available, and since the engine was to be supercharged, Smokey selected a set of top quality Carrillo steel rods with S.P.S. bolts for this engine. The pistons used are special aftermarket dished forgings, which were finish machined by Diamond Racing Engines (3493 Ten Mile Road, Warren, MI 48091). Chevrolet .927 -inch-

diameter piston pins, cut to a length of 2.75 inches, were used with double .042-inch Tru-Arc pin locks to retain the floating pins. Piston-to-wall clearance was set at .008-inch. Speed-Pro piston rings handle the sealing. The top ring is a 1/ 16-inch moly-faced ductile-iron version,

and the second ring is a cast-iron reverse torsional twist design. A conventional three-piece 3/ 16-inch oil ring is used.

With the bottom end pieces select-ed, modified ' and fitted, Stradley Auto Parts in Titusville, Florida, handled the balancing. Smokey then assembled the short-block. Main cap studs are used in conjunction with a Moroso block girdle. Installing this girdle takes a lot of patience and trial-and-error shimming to avoid distorting the block to the point where it binds the crank-shaft, but when correctly installed, it does add a lot of strength to the block.

Camshaft selection for this engine was crucial. Remember, the goal was to have been around 300 hp, yet the engine needed to be streetable with a

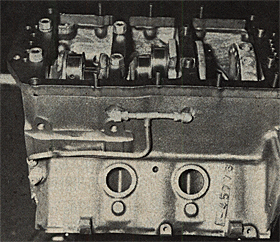

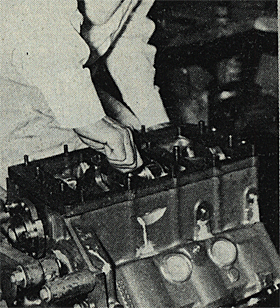

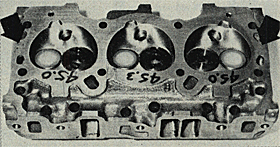

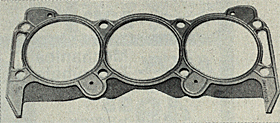

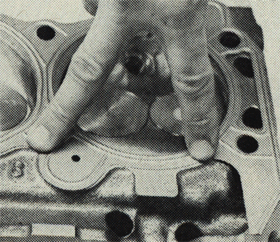

These are extra water jacket core holes on the 4.1 - liter block. A standard 3.8 - liter head gasket has been laid atop the block to show how these holes aren't covered. The new gasket covers them, but the next photo shows the problem.

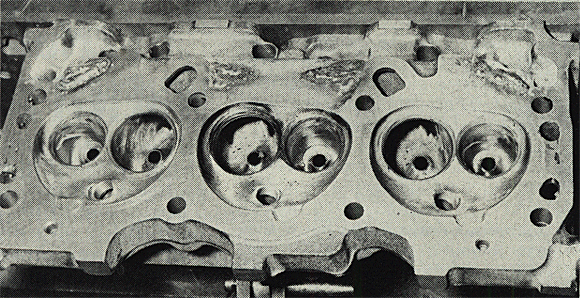

You can see here how the heavy - duty cylinder head does not have the mating face extended to cover the water jacket core holes in the block. Consequently, the gasket would not be supported and water leaks would occur.

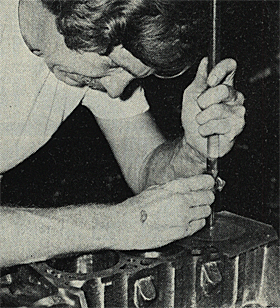

decent idle and capable of delivering good fuel economy, which translates into low-speed efficiency. To meet these needs, Smokey selected a Crane H-2141293-2-12 grind. This hydraulic tappet cam features 214 degrees duration at .050-inch tappet lift and is cut with 112-degree lobe center spacing. The cam timing is as follows: Intake opens 31 degrees before top center, intake closes 73 degrees after bottom center; exhaust opens 80 degrees be-fore bottom center, and exhaust closes 34 degrees after top center. The overlap on this cam is only 65 degrees for a smooth idle and excel-lent low-rpm torque and throttle response, yet the power range is from 2500 to 5500 rpm with a suggested maximum rpm of 7000. Since the cam was to be used with Crane 1.6:1 (stock is 1.55:1) needle-bearing aluminum rocker arms, the lift would be .469-inch on the intakes and .494-inch on the exhaust valves. Driving the cam is a Cloyes roller chain and sprocket set, and the cam is degreed-in exactly on time.

The cylinder heads for this' engine are the latest heavy-duty versions (part No. 25500001). As mentioned' earlier, Smokey welded up' the end water pas-sages for improved strength and gasket sealing. Additionally, the heads have been fully ported and polished by Diamond Racing Engines. The valves used are modified Chevrolet small-block valves cut down to the Buick V6 performance diameters of 1.75 inches on the intake and 1.5 inches on the exhaust. These valves also provide valve stem length .065-to .070-inch longer than the Buick valves, for in-creased valve spring installed height, which is desirab..le with performance cams. It also permits the use of small-block Chevrolet valve springs after the spring pads have been cut to a 1.550-inch diameter. To retain proper valve-train geometry with the longer valves, specially made spacers are used under the heavy-duty rocker arm shafts. Special Crane push rods are also used, along with the Crane aluminum rocker arms mentioned earlier.

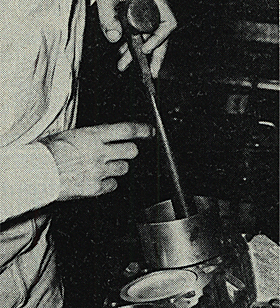

Installation of the heads turned out to be a problem. Buick has a new cylinder head gasket to properly cover the extra water jacket core holes on the new 4.1-liter block decks, but the , machined mating face on the heavy-duty cylinder heads had not been ex-tended. Consequently, there was not enough material on the cylinder head side of the gasket above the core holes to complete the gasket seal. The result is a

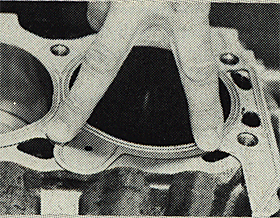

total of eight substantial water leaks! Buick is supposed to be correcting the head configuration to eliminate this oversight, but Smokey solved the problem by welding the deficient areas and then resurfacing the heads. The accompanying photos show the problem. If you're building a 4.1-liter Buick V6, close attention must be given to this potential problem area.

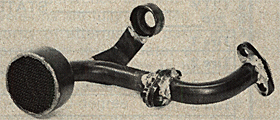

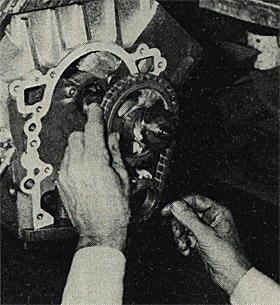

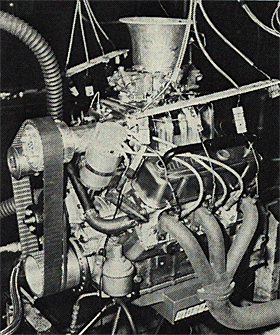

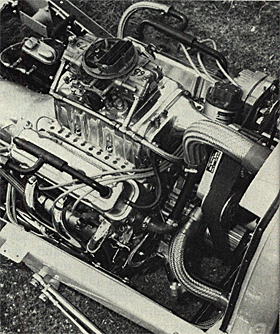

Completing the remainder of the basic engine is a Moroso oil pan and pickup, a remote dual oil filter arrangement, a Buick heavy-duty mechanical fuel pump, Moroso aluminum valve covers and breathers, a Ronco Vertex magneto, Accel 8mm plug wire and Champion BL-60 spark plugs, and a set of handmade 3-into-1 headers designed by Smokey. Of course the real story is atop the engine, with Dyer Machine Service's new small Roots-type supercharger. Dyer has developed his own aluminum blower manifold for the Buick V6, and his own blower drive pieces. Consequently, it's a simple bolt-on kit, utilizing a Holley 600-cfm carb atop the blower.

After final assembly, the engine was run-in under a light load on the dyno for 1 Y2 hours, after Which it was re-torqued and the timing reset to verify a total of 35 degrees. When everything was to Smokey's liking, a power, run was made with the blower driven six percent under crankshaft speed, which produced no observable boost pressure at speeds up to 5600 rpm, but the engine still produced 262 hp at 5600 rpm (see chart). Apparently Dyer's new blower is set up with very loose tolerances for trouble free street operation. Consequently, the drive pulleys were changed to run the blower 41 percent faster than the crankshaft, which produced boost from 2000 rpm on up. In this configuration, Smokey's V6 pumped out 343 hp at 6000 rpm. yet it would idle smoothly and quietly.

In every way, our search for an ideal lightweight, compact, powerful and economical enthusiast engine had been realized. It would be ideally suit-ed to a street rod-and as you might have already guessed, that's exactly where it's headed. Next month we'll bring you the first installment on our latest project-a '32 highboy roadster being built by Total Performance in Wallingford, Connecticut. People who have seen this glittering little engine already nestled in the Total Performance chassis ask, " What is it?" When told it's a Smokey Yunick built blown Buick V6, the questioning jaws gape and the eyes bulge-we think yours will too when you see the final package! HR

Smokey corrected the problem by building up the heads with weld in the required areas. The heads were then resurfaced. Buick will alter future heavy - duty heads to include this extra metal.

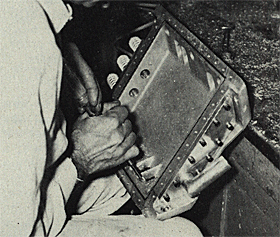

Dyer has even designed his own blower manifold for the Buick V6 so that modification of stack manifolds isn't required. Since the new manifold is designed for use with both late - model raised part heads and earlier low port heads, the port openings must be enlarged to match the raised port openings. This is a simple job that takes only a few minutes with a die grinder.

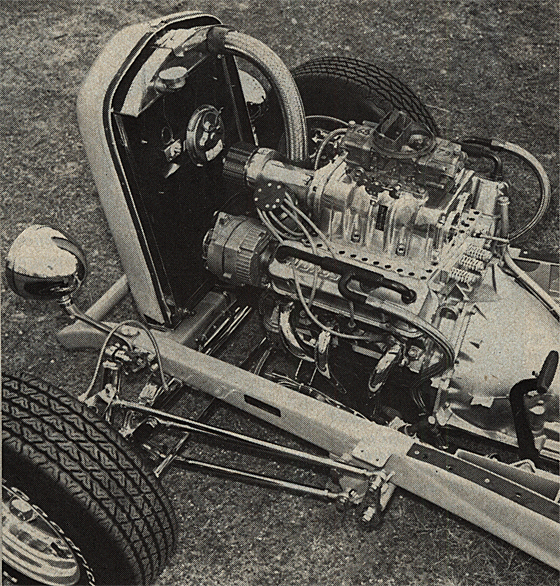

Completed, the Moroso/Yunick water outlet, Moroso valve covers, Moroso oil pan, Buick heavy- duty fuel pump, Ronco Vertex mag, Dyer blower and drive, and the 3 - into - 1 headers are clearly visible. Probes in the headers monitor exhaust gas temperature on the dyno.

Fully detailed, this is what the finished engine looks like sitting in a very nice '32 Ford street rod chassis - but more on that next month!

(6% under driven) |

(6% over driven) |

|||