Of course, there are those who balk at the suggestion, pointing out that late-model hardware in an old skin might be easy for Chevy and Ford guys, but not for those with more particular tastes-guys who dig cars and engines that haven't been made for decades. One of our friends motors a '67 Buick Skylark daily, and he was sick of the lame two-speed automatic trans behind its 340 four-barrel V-S.

For starters, he thought that he had a Power glide, but in fact, the 'Glide was only used behind Chevrolet engines (yes, there were some rare exceptions). The rest of the GM lineup utilized a two-speed of a different design, often called the Super Turbine 300. Commonly found under mid-'60s Buicks, Oldsmobile's, and Pontiacs, the ST300 was only offered with a BOP bell housing pattern and is slightly beefier internally than the 'Glide. Some non-Chevy six-cylinders used this slush box as well, and many were air-cooled, with a bell housing that

from: Hot Rod, August, 2000

looked as if it had been hole-sawed and sheet metal fins tack-welded to the torque converter.

The ST300 in this particular Buick functioned adequately, but the owner

We turned up a 200-4R at the Pick-Your-Part salvage yard. It was offered in various GM passenger cars beginning in 1981, but some cars were equipped with three-speed automatics while other (full size models) used the 700-R4. We wanted one of the latest examples because it would include all of the running upgrades GM instituted over its life (1981 - 1990). We passed on full size cars, and wagons in particular, because their gross weight and the possibility of trailer - towing degraded the odds of finding a sound unit. We settled on the one from this '86 Cutlass, which was likely to have all the upgrades and showed bright red fluid.

Two of use yanked the 200 in about a half - hour; in another hour, some cleaning solvent and a wire brush had it looking almost new. Be careful not to spray water haphazardly, as it can get inside through the dipstick tube bore, the vent, the cooler line fittings, and the output shaft. We took the torque converter, the dipstick and tube, and the throttle - valve (TV) cable and bracket from the donor car as well. Hang on to any hardware, as much of it is metric and won't interchange with older fasteners.

complained that the car was a dog and sucked down more gas than even a four-barrel V-8 has a right to. Investigation revealed that the ST300 has a 1.64:1 low gear ratio which is even higher than a power glide's 1.76:1. To put that in proper perspective, a TH700-R4 has a Second gear ratio of

The 340 and its 300ci cousin are kind of like mini nailheads. In '68, Buick retired them in favor of the new 350 small - block, which was a smaller version of the big - block Buick V-8s that debuted in 1967. Despite the demise of this engine, the bell housing pattern is the same BOP configuration used for many years following, and allows the later 200-R4 to bolt up. Begin by disconnecting the batter. We found it easier to access the top two bell housing bolts from the engine bay.

1.63:1. In addition, Buick's version of the ST300 used a "Switch-Pitch" torque converter - GM's trade name for its variable stall-speed torque converter that could alter stall rpm between two fixed rates. The idea was to provide higher stall at takeoff and then tighten it up at cruising speed. Our

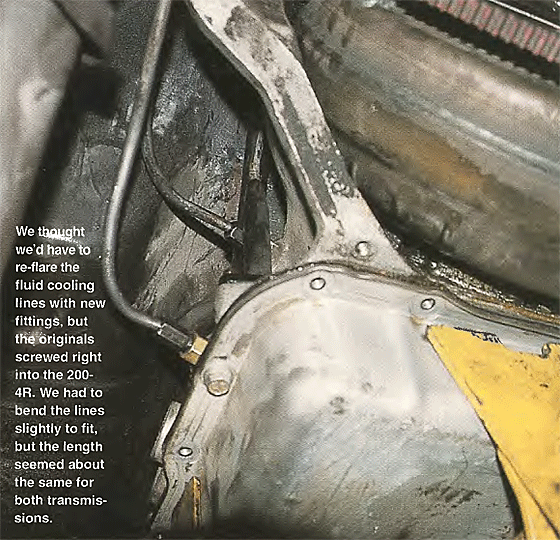

Remove the fluid cooler lines from the passenger side of the transmission case. Use a line wrench if possible, and don't mangle the lines or the fittings, as they will be reused. Some mechanics find it easier to remove the lines after the trans is partially lowered from the car.

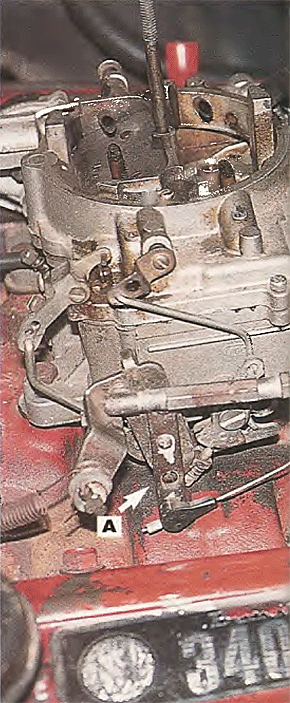

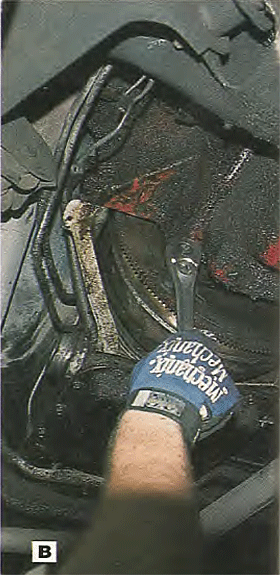

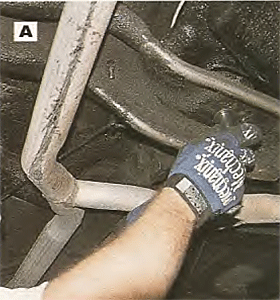

Underneath, we begin by removing the cover over the flex plate and torque converter (A) and then pull the starter. Unfasten the three bolts that hold the torque converter to the flex plate (B). You'll have to turn the engine (by hand) to expose each bolt individually. When all three are out, push the converter back towards the transmission.

Buick's Switch-Pitch function had long since capitulated and seemed to be locked in the low rpm stall, making it a real pig out of the hole.

These revelations prompted this anxious man to contemplate a swap, and his first thoughts

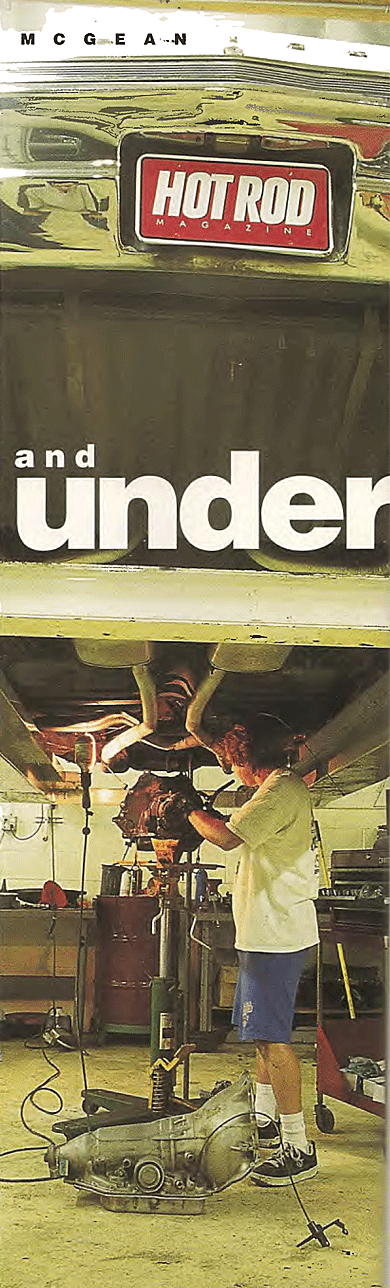

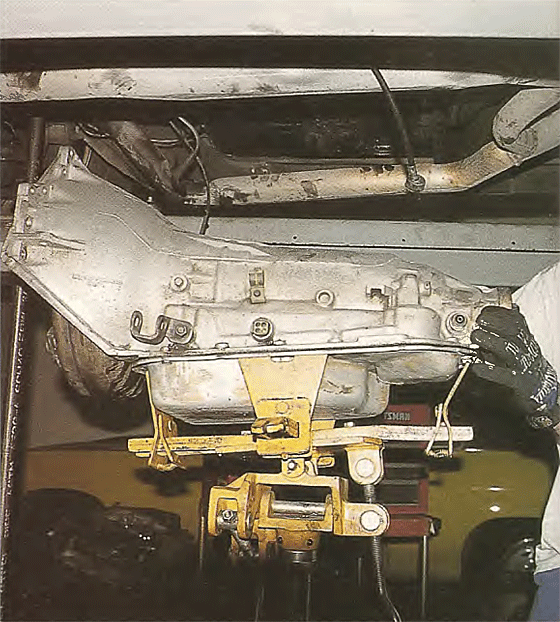

Unbolt the transmission mount from the cross member (A) and unbolt the cross member from the frame (B). Because the trans sits on the member, and the member sits on the frame, everything will stay in place without the fasteners. Pull the drive shaft, unscrew the speedo cable, disconnect the shift linkage, and remove the four remaining bell housing bolts. Then, with the transmission jack (or a suitable substitute) supporting the trans, slide the cross member back and lower the transmission from the car.

were the Turbo 350. When asked why he didn't consider going one more step to an overdrive box, the owner responded that using a 700- R4 would require adapters, and he didn't want to deal with the expense or complication. But what of the 200-R4? This lesser - known transmission also features overdrive, and was commonly produced with a BOP bell housing

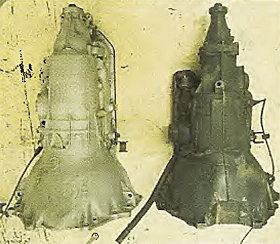

With the ST300 lined up with the 200-R4, we verify a common overall length of 27 3/4". The main physical difference is the position of the transmission mount; the ST300's pad is 20 1/8 inches from the bell housing while the 200-4R's is 26 13/16 inches from the bell housing That difference might appear to be a problem at first, but the TH400 also has its mount pat 26 13/16 inches from the bell housing, and since our Buick was available with a TH400, the cross member should mount in that position without a problem.

pattern. General Motors introduced the 200-R4 in the '81 model year, and the most common applications are A- and G-body vehicles (Caprice, Delta 88, Regency 98, Electra, LeSabre, Bonneville, Catalina).

For BOP fans, the 200-4R is a godsend, in addition to the BOP bell housing, it also

One of our concerns regarded torque converter mounting. A specialist had noted that the Buick would have a flat flex plate while most Chevy ones have a raised pad around each torque converter mounting bolt. The problem would be that the converter hub would seat in the back of the crank before the mounting lugs were flush with the flex plate We thought it might need spacers, but since our trans came from an Olds engine, which also uses a flat flex plate, the mounting lugs on the converter had the proper dimensions and bolted up perfectly. Like many GM flex plates, ours was drilled with two patterns; the 200 used the larger of the two, which are intended for a TH400.

features an overall length that is identical to the TH350 and the ST300, and it uses the same 27'spline output shaft. This meant that we would gain a tall 0.67:1 Overdrive, and realize a nice, deep 2.74:1 First gear, and we'd do it without adapters or a modified drive shaft. Even scoring the 200-R4 at the junkyard is easier than finding a 700-R4, since herds of cabbies and light truck owners scarf them up right alongside all the Chevy hot rodders. Even the Chevy guys can benefit from the 200, as many have a universal bell housing pattern (all

'80s Monte Carlos with OD used it).

Though we've outlined the swap of a 200-R4 in place of the ST300 two-speed in our oddball 340 - powered Buick, it will work just as well with Pontiac or oldsmobile V-8s.

When we finished, the Buick was able to lunge from stoplights as well as loaf down the freeway sipping fuel. After the first week on the road with the new trans, calculations revealed a 60 - percent improvement in fuel economy. It was well worth the effort.

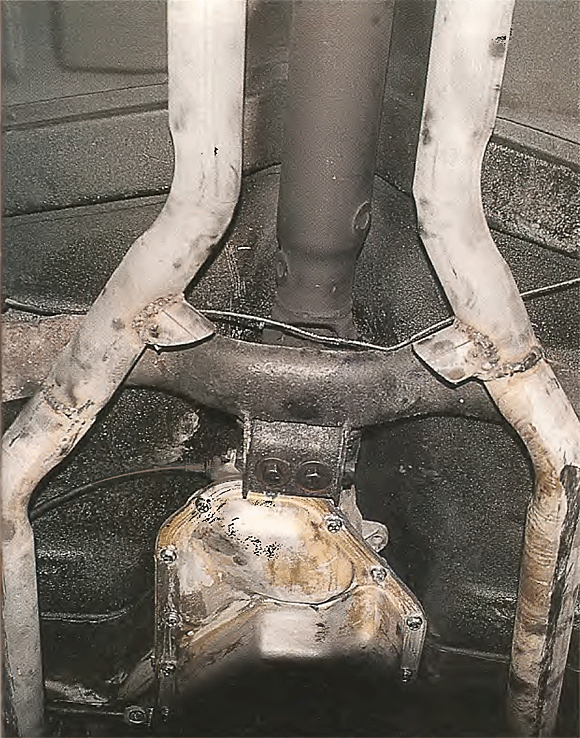

Since the Buick's original cross member is flat and straight across, it partially blocks the 200's fluid pan, which extends nearly to the end of the case. We averted the problem by using a Chevy cross member, which is tubular in design and curves rearward so that a separated platform, welded to the member, can "reach" forward to accept the trans mount. Most '64 - '72 Chevelles use this type, which bolts into the Buick. We found ours at Memory Lane classic auto salvage in Sun Valley, California. Incidentally, if your car has custom - bent dual exhaust (like ours), your pipes may not clear the cross member after it is moved rearward. This situation required the removal of the crossover tube in our system.

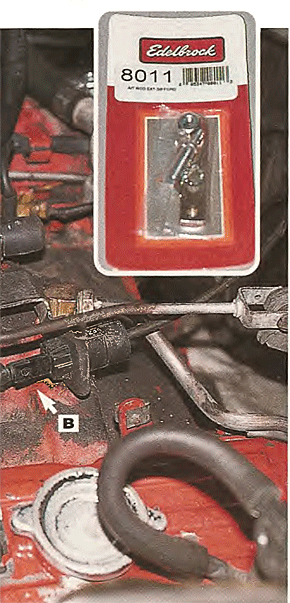

Below: A 200-4R throttle-valve (TV) cable resembles the kick-down cable seen on TH350s, but it actually functions as a throttle position sensor for the transmission, raising line pressure as the throttle opening increases and providing input for shift points. The TV is so vital to proper shifting that the 200 doesn't use a vacuum modulator, like the TH350 and 400. Our Buick's original Carter carb had no provision to connect the TV, since the ST300 didn't use a kick down cable. By using an Edelbrock kit (PN 8011) intended for a Ford automatic trans lever of similar function (inset), we were able to provide a lever for the TV cable (A). We modified the mounting bracket from the donor Cutlass Q-Jet to fir the back of the Carter and adjusted the cable using the factory ratcheting slide (B).

Left: The shift linkage attachment from the ST300 (left) centered on the spindle in the trans, while the one from the 200 is offset. We simply bolted the Buicks original to the 200 and connected the rest of the column shift linkage, which worked perfectly.

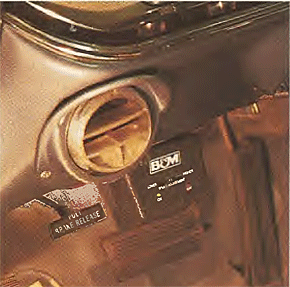

The 200-4R's lock-up torque converter was originally controlled by the onboard computer of the host Cutlass, but since our '67 Buick has no ECU, we needed a control for the lock-up function. B&M offers this control kit for the lock-up converter, which also allows the driver to alter the timing of this operation. Omitting the lockup is not recommended, as the converter will slip excessively in Overdrive due to the extra load.

The B&M is easy to install. First, connect the 3-inch cable to the speedometer output of the trans, and then connect the speed sensor, also provided in the kit, to the short cable. The factory speedo cable will then connect to the speed sensor.

The control box mounts to the dash, and the wiring harness has GM-style plugs to mate to the speed sensor and the lock-up plug on the side of the 200-R4. The only other requirement is to ground one wire at the trans and another to the chassis. One remaining wire must be connected to key-on power, which our Buick's fuse box provided. The slide on the control box determines when the converter locks up. HR

B7M Racing and Performance Products

Dept. HR08, 9142 Independence Ave., Chatsworth, CA 91311

818/882-6422: www.bmracing.com

Edelbrock Corporation

Dept. HR08, 2700 California St., Torrance, CA 90503

310/781-2222; www.edelbrock.com

Memory Lane

Dept. HR08, 11311 Pendleton St., Sun Valley, CA 91352;

800/AT1-YARD; www.oldautoparts.com

Pick-Your-Part

Dept. HR08, 11201 Pendleton St., Sun Valley, CA 91362;

800/962-CARS; www.pickapart.com