How to check the oil in a Buick convertible top, 1966

HYDRAULIC CHECKING PROCEDURE

Failures in the hydraulic system can be caused by lack of hydraulic fluid, leaks in hydraulic system, obstructions or kinks in hydraulic hoses or faulty operation of a cylinder or pump.

1. Checking Hydraulic Fluid Level in Reservoir

- Operate top to raised position.

- On "A" body styles, at rear compartment, remove pump and motor shield

- On "B & C" body styles perform the following operations:

- Detach front edge of folding top compartment bag from rear seat back panel.

- Remove clips securing hydraulic hose to rear seat back panel.

- Disengage pump attaching grommets from compartment pan brace.

- Place absorbent rags below reservoir at filler plug.

- With a straight-bladed screwdriver, remove filler plug. Fluid level should be within 1/4 inch of lower edge of filler plug hole.

- If fluid is low, add Delco #11 Hydraulic Fluid (GM Hydraulic Brake Fluid Super #11 or its Equivalent to bring to specified level. See "filling of Hydro-Lectric Reservoir".

- Install filler plug.

- On "A" body styles, install pump and motor shield.

- On "B & C" body styles install motor and pump assembly and all previously removed parts.

2. Checking Operation of Lift Cylinders

- On all styles remove rear seat cushion and folding top compartment side panel assemblies. On "B & C" body styles remove rear seat back.

- Operate folding top control switch and observe lift cylinders during "up" and "down" cycles for these conditions:

- If movement of cylinder is uncoordinated or sluggish when the motor is actuated, check hydraulic hoses from motor and pump to cylinder for kinks.

- If one cylinder rod moves slower than the other, cylinder having slower moving rod is defective and should be replaced.

- If both cylinder rods move slowly or do not move at all, check the pressure of the pump. See "Checking the Pressure of the Pump".

NOTE :To insure proper operation of the lift cylinders, the top lift cylinder rods should be cleaned and lubricated at least twice a year. To perform these operations, raise top to "up" position and wipe exposed portion of each top lift cylinder piston rod with a cloth dampened with brake fluid to remove any oxidation and/or accumulated grime. With another clean cloth, apply a light film of brake fluid to the piston rods to act as a lubricant.

CAUTION : Exercise care so that brake fluid does not come in contact with any painted or trimmed parts of the body.

- Remove motor and pump assembly from rear compartment.

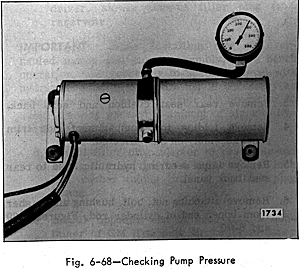

- Install plug in one port, and pressure gauge in port to be checked. See Figure 6-68.

- Actuate motor with applied terminal voltage within range of 9.5 volts to 11.0 volts. Pressure gauge should show a pressure between 340 psi and 380 psi.

- Check pressure in other port.

NOTE : A difference in pressure readings may exist between the pressure port for top of cylinders and pressure port for bottom of cylinders. This condition is acceptable if both readings are within the limit of 340 psi and 380 psi.

- If the pressure is not within specified limits, unit is defective and should be repaired, as required.