| BOLT TORQUE SPECIFICATIONS | ||

| LOCATION | THREAD SIZE | TORQUE |

| Spark Plug | 14MM | 22-28 |

| Crankcase Drain | 28MM | 30-35 |

| Lower Crankcase | 5/16-18 | 6-15 |

| Flywheel Housing to Upper Crankcase | 7/16-14 | 55-60 |

| Timing Gear Cover | 3/8-16 | 15-20 |

| Valve Push Rod Cover | 5/16-18 | 4-5 |

| Valve Rocker Arm Cover | 5/16-24 | 4-5 |

| Water Pump Mounting | 3/8-16 | 25-30 |

| Manifold Stud | 3/8-24 | 25-30 |

| Cylinder Head | 7/16-14 | 65-70 |

| Con. Rod Bolt - Series 40-50 | 3/8-24 | 40-45 |

| Con. Rod Bolt - Series 70 | 7/16-24 | 60-65 |

| Piston Pin Clamp | 5/16-24 | 25-30 |

| Crankshaft Bearing Clamp | 1/2-13 | 90-100 |

| Balancer Retaining | 3/4-16 | 100-110 |

| Flywheel to Crankshaft, Synchromesh | 3/8-24 | 35-40 |

| Flywheel to Crankshaft, Dynaflow | 7/16-24 | 50-55 |

| Rocker Arm Shaft Bracket | 3/8-16 | 30-35 |

| Rocker Arm Shaft Bracket Stud | 3/8-24 | 30-35 |

| Generator to Bracket Bolt | 3/8-24 | 25-30 |

| Generator Mounting Bracket to Crankcase | 3/8-16 | 30-35 |

| Front Engine Mounting Bracket to Frame Bolt | 3/8-24 | 30-35 |

| Front Engine Mount Stud | 3/8-24 | 30-35 |

| Transmission Mounting Pad to Rear Bearing Retainer | 3/8-16 | 30-35 |

| Transmission Mounting Pad to Transmission Support Bolt | 3/8-24 | 30-35 |

| Transmission Support to Fame Cross Member Bolt | 3/8-24 | 20-25 |

| Thrust Pad to Transmission Support and Thrust Plate | 3/8-24 | 30-35 |

| GENERAL SPECIFICATIONS | ||

| General Information

Items |

Series 40-50 | Series 70 |

| Type | <------------Valve in Head-----------> | |

| Cylinders and Arrangement | <---------------8 in Line-------------> | |

| Bore and Stroke | 3 3/16" X 4 1/8” | 3 7/16"X 4 5/16” |

| Piston Displacement | 263.3 | 320.2 |

| Compression Ratio | ||

| Synchromesh - Series 40 Only | 6.6 to 1 | --- |

| Synchromesh - Series 50 Only | 6.9 to 1 | --- |

| Dynaflow - All Series | 7.2 to 1 | 7.5-1 |

| Compression Pressure @ Cranking Speed (psi) | ||

| Synchromesh - Series 40 Only | 114 | --- |

| Synchromesh - Series 50 Only | 118 | --- |

| Dynaflow - All Series | <-----------------120----------------> | |

| Firing Order | <----------1-6-2-5-8-3-7-4----------> | |

| Taxable Horsepower | 32.51 | 37.81 |

| Max B.H.P. @ RPM. | ||

| Synchromesh - Series 40 Only | 120 @ 3600 | --- |

| Synchromesh - Series 50 Only | 124 @ 3600 | --- |

| Dynaflow - All Series | 128 @ 3600 | 168 @3800 |

| Engine Weight, Less Clutch and Mountings (lbs.) | 746 | 749 |

| 833 | ||

| Number of Mounting and Material | <----------3 Synthetic Rubber---------> | |

| Cylinder Crankcase and Cylinder Head | ||

| General Information

Items |

Series 40-50 | Series 70 |

| Cylinder Crankcase Type | <---Black Cast Integral with Crankcase---> | |

| Cylinder Head Type and Material | <----------One Piece, Cast Iron---------> | |

| Combustion Chamber | <---------------Cast in Head------------> | |

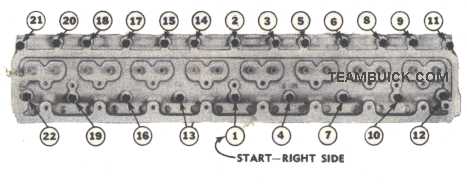

| Head Bolts, Number and Diameter | <----------------22, 7/16″--------------> | |

| Crankshaft Bearings, Flywheel Balancer | ||

| Crankshaft Weight (lbs.) | 90 | 116 |

| Number of Crankshaft Bearings | 5 | 5 |

| Bearing Which Takes Thrust | <-----------------Center----------------> | |

| Crankshaft Bearing Type | <-------------Replaceable Liners----------> | |

| Crankshaft Bearing Material | <---------Steel Backed Durex 100A-------> | |

| Provision for Bearing Adjustment | <-----------------None------------------> | |

| Bearing Cap Bolts, No. and Diam. | ||

| Rear Bearings | Two 1/2” | Four 1/2” |

| Other Bearings | Two 1/2” | Two 1/2” |

| Flywheel | ||

| Material and Weight, Synchromesh | C.I.-36.56 | --- |

| Material and Weight, Dynaflow | Steel - 9.23 | Steel - 12.21 |

| Number of Teeth on Ring | 146 | 156 |

| Crankshaft Balancer Type | <--Laminated Steel Flywheel on Steel Leaf Springs--> | |

| Balancer Location | <---------Front End of Crankshaft---------> | |

| Connecting Rods, Pistons and Rings | ||

| Connecting Rod Bearing Type | <---------Steel Backed Durex 100-A--------> | |

| Connecting Rod Bearing Material | <--------------Replaceable Liners------------> | |

| Provision for Bearing Adjustment | <------------------None-------------------> | |

| Number and Diam. of Cap Bolts | Two 3/8” | Two 3/8” |

| How are Rods and Pistons Removed | <-----------From Top of Cylinder-----------> | |

| Piston Type | <----------------Full Skirt----------------> | |

| Piston Material and Surface Treatment | <--------Aluminum Alloy - Anodized-------> | |

| Compression Rings Per Piston | 2 | 2 |

| Type | <--------------Inside Bevel---------------> | |

| Oil Rings Per Piston | 2 | 2 |

| Type, Upper | <-------Channeled - Oil Return Slot-------> | |

| Type, Lower | <----------------Flex-Fit-----------------> | |

| Location of All Piston Rings | <------------Above Piston Pin------------> | |

| Camshaft and Valve Mechanism | ||

| Camshaft Drive | <-------------Link Belt Chain------------> | |

| Number of Camshaft Bearings | 5 | 5 |

| Camshaft Bearing Material | <----------Steel Backed Babbitt---------> | |

| Camshaft Thrust Control | <-----------Plate at Front End-----------> | |

| Camshaft Sprocket | ||

| Material and Width | <------------Cast Iron, 13/16″-----------> | |

| No. of Teeth | 38 | 38 |

| Crankshaft Sprocket | ||

| Material and Width | <--------------Steel, 13/16″-------------> | |

| No. of Teeth | 19 | 19 |

| Timing Chain Width | 13/16” | 13/16” |

| Valve Lifter Type | ||

| Series 40, Synchromesh only | Plain Sleeve | --- |

| Series 50, All Dynaflow | <---------------Hydraulic----------------> | |

| Valve Type | ||

| Inlet | <--------------Streamlined---------------> | |

| Exhaust | <---------------Mushroom----------------> | |

| Valve Seat Angle, Inlet and Exhaust | <--------------45 Degrees---------------> | |

| Valve Spring Type | <--------------Dual Helical---------------> | |

| Valve Guide Type and Material | <---------Removable, Cast Iron-----------> | |

| Engine Oiling System | ||

| Oiling System Type | <--------------Forced Feed---------------> | |

| Oil Supplied to Bearing Surfaces - | ||

| Crankshaft Bearings | <----------------Pressure-----------------> | |

| Connecting Rod Bearings | <----------------Pressure-----------------> | |

| Pistons and Pines | <-----------------Spray-------------------> | |

| Camshaft Bearings | <----------------Pressure-----------------> | |

| Timing Chain and Sprockets | <----------Metered Jet and Spray---------> | |

| Rocker Arms and Valves | <--------------Low Pressure--------------> | |

| Valve Lifters | <--------------Low Pressure--------------> | |

| Location of Oil Filter | <--------In Valve Rocker Arm Cover-------> | |

| Location of Oil Drain | <----------Plug in Lower Crankcase--------> | |

| Oil Reservoir Capacity - Quarts (add 1 1/2 qts for dry oil filter | ||

| Dry Engine | 6 | 8 |

| Refill | 5 1/2 | 7 |

| Oil Level Gauge | <---------Rod in R. Side of Crankcase--------> | |

| Oil Level Pressure Gauge Make | <-------------------A/C------------------> | |

| Normal Oil Pressure | <------------35 lbs. at 35 mph.-----------> | |

| Oil Pump Type | <---------------Helical Gear--------------> | |

| Oil Pump Location | <------Suspended in Lower Crankcase-----> | |

| Oil Screen Location | <-------On Float Attached to Pump-------> | |

| Oil Pressure Regulator Type | <-----Non-Adjustable Spring and Valve-----> | |

| Engine Cooling System | ||

| Cooling System Type | <----------------Pressure-----------------> | |

| Water Temperature Control | <-------Thermostat and Fixed Bypass------> | |

| Cooling System Capacity - Quarts (Add 1 1/2 qts. for Dynaflow) | ||

| Less Heater | 12 | 18 |

| With Heater | 13 1/2 | 19 1/2 |

| Location of Drains | <-Cocks in Rad. and in R.H. Side of Crankcase-> | |

| Water Pump Type | <---------------Centrifugal----------------> | |

| Water Pump Location | <---------Front End of Crankcase----------> | |

| Water Pump and Fan Drive (With Generator) | <----------Single Vee Belt-------------> | |

| Water Pump to Crankshaft Speed Ratio | <-----------------0.9 to 1----------------> | |

| Water Pump Bearing Type | <---------Sealed Double Row Ball----------> | |

| Water Pump Seal Type | <---------Spring Loaded, Packless---------> | |

| Fan Diameter | <------------------18"--------------------> | |

| Number of Blades | 4 | 5 |

| Radiator Make | <------------------Harrison---------------> | |

| Core Type | <---------------Vee Cellular---------------> | |

| Core Material | <------------------Copper----------------> | |

| Core Frontal Area (sq. in.) | ||

| Synchromesh | 415 | --- |

| Dynaflow | 484 | 484 |

| Core Thickness | 2” | 3” |

| Radiator Pressure Control | <-------------Valve in Filler Cap-----------> | |

| Radiator Pressure | <------------------7 lbs.-----------------> | |

| Radiator Thermostat - Make | <-----------------Harrison----------------> | |

| Thermostat Location | <-------In Housing Above Water Pump-----> | |

| ENGINE DIMENSIONS AND FITS NOTE:Dimensions and limits for fir of parts apply to new parts only. Where limits are given, "T" means tight and "L" means loose. *A11 Measurements in Inches Unless Otherwise Specified. |

Crankshaft and Connecting Rod Bearings |

||

Series 40-50 |

Series 70 |

|

Crankshaft Bearing - Nominal Diam. X Length |

||

-Front |

2 9/16" x 1 17/64” |

2 9/16" x 1 9/32” |

-Front Center |

2 9/16" x 1 1/32” |

2 5/8" x 31/32” |

-Center |

2 9/16" x 1 35/64” |

2 11/16" x 1 15/32” |

-Rear Center |

2 9/16" x 1 1/32” |

2 13/16" x 2 15/32” |

-Rear |

2 9/16" x 1 25/32” |

2 13/16" x 2 15/32” |

Crankshaft Journal Diameter |

||

-Front |

2.5625" - 2.5632” |

2.5605" - 2.5615” |

-Front Center |

2.5625" - 2.5632” |

2.6235" - 2.6245” |

-Center |

2.5625" - 2.5632” |

2.6855" - 2.6865” |

Center Rear |

2.5625" - 2.5632” |

2.7485" - 2.7495” |

-Rear |

2.5625" - 2.5632” |

2.8105" - 2.8115” |

Fillet Radius |

.125" |

|

Thrust Width |

1.5490" |

|

Crankshaft Bearing to Journal Clearance |

.0006" - .0018” |

.0006" - .0020” |

Crankshaft End Play at Center Bearing |

.004" - .008” |

|

Fit to Main Drive Gear Pilot Bearing in Crankshaft |

.004"T to .0012"L |

--- |

Connecting Rod Bearing Nominal Diam. x Length |

2 1/8" x 1.030” |

2 1/4" x 1.306” |

Crank pin Journal Diameter |

2.125" - 2.126” |

2.248" - 2.249” |

Crank pin Journal to Bearing Clearance |

.0005" - .0016” |

|

End Clearance to Connecting Rod on Crank pin |

.005" - .010” |

|

Connecting Rod Length, Center to Center |

7 3/8” |

8 1/4” |

Cylinders, Pistons, Pins and Rings |

||

Cylinder Bores, Standard Size |

3.186" - 3.189” |

3.436" - 3.439” |

Piston Length, Overall |

3 49/64” |

4 9/16” |

Piston Diameter, Top of Skirt, at 90° to Piston Pin - |

||

-Standard |

3.1860" - 3.1872” |

3.4358" - 3.4370” |

-.005" Oversize |

3.1916" - 3.1922” |

3.4414" - 3.4420” |

-.010" Oversize |

3.1966" - 3.1972” |

3.4464" - 3.4470” |

-.020 Oversize |

3.2066" - 3.2072” |

3.4564" - 3.4570” |

-.30" Oversize |

3.2166" - 3. 2172” |

3.4664" - 3.4670” |

Piston Clearance in Cylinder Bore at Top of Skirt |

.0012" - .0018” |

.0014" - .0020” |

Piston Fit @70º F., using Feeler Gauges, Allowing Piston to Drop on its Own Weight |

.0015" GO - .002" NO GO |

|

Piston Pin Length |

2 11/16” |

3 1/16” |

Piston Pin Diameter |

.8124" - .8129” |

.8744" - .8749” |

Piston Pin Fit in Piston at 70º F. |

Finger Push Fit (.0003" - .0005") |

|

Width of Compression Rings |

3/32” |

3/32” |

Width of Channeled Oil Rings |

3/16” |

3/16” |

Width of Flex-Fit Oil Rings |

.186" - .187” |

|

Width of Gap, Ring in Bore - |

||

-Compression and Upper Oil Ring |

.010" - .020” |

|

Flex-Fit Oil Ring |

No Checking or Fitting Required |

|

Side Clearance of Rings in Piston Grove - |

||

-Compression Ring |

.0015" - .0035” |

|

-Upper Oil Ring |

.0015" - .003” |

|

-Flex-Fit Ring |

.001" - .003” |

|

Camshaft and Valve Mechanism |

||

Camshaft End Play |

.004" - .009” |

|

Camshaft Bearings - Diam. x Length - |

||

-No. 1 |

2 5/32" x 1 1/8” |

|

-No. 2 |

2 1/8" x 3/4” |

2 1/8" x 1 1/8” |

-No. 3 |

2 3/32" x 1 1/8” |

|

-No. 4 |

2 1/16" x 3/4” |

2 1/16" x 15/16” |

-No. 5 |

1 3/4" x 31/32” |

|

Camshaft Clearance in Bearings |

.0015" - .004” |

|

Valve Lifter Diameter |

.9975" - .9985” |

|

Valve Lifter Clearance in Crankcase |

.0005" - .0025” |

|

Rocker Arm Shaft O. D.> |

13/16” |

13/16” |

Rocker Arm Clearance on Shaft |

.002" - .004” |

|

Valve Head Diameter - |

||

-Inlet |

1 17/32” |

1 25/32” |

-Exhaust |

1 11/32” |

1 7/16” |

Valve Seat Angle - Inlet and Exhaust |

45º |

|

Rocker Arm Ratio - |

1.45 |

|

Valve Lift - |

||

-Inlet |

.348” |

.347” |

-Exhaust |

.342” |

.348” |

Valve Stem Diameter - |

||

-Inlet |

.3715" - .3719” |

|

-Exhaust |

.3711" - .3719” |

|

Valve Stem Clearance in Guide - |

||

-Inlet |

.0015" - .0035” |

|

-Exhaust |

.0021" - .0039” |

|

Valve Guide Extension from Top of Cyl. Head |

1 5/32” |

1 5/32” |

Inner Valve Spring, Used with Adjustable Valve Lash - |

||

-Valve Open (lbs. @ length) |

48 - 54 @1 5/16” |

--- |

-Valve Closed (lbs. @ length) |

17.5 - 22.5 @ 1 21/32” |

--- |

Outer Valve Spring, Used with Adjustable Valve Lash - |

||

-Valve Open (lbs. @ length) |

74 - 80 @1 19/32” |

--- |

-Valve Closed (lbs. @ length) |

29.5 - 34.5 @ 1 15/16” |

--- |

Inner Valve Spring, Used with Hydraulic Lifters - |

||

-Valve Open (lbs. @ length) |

49 -55 @1 5/16” |

|

-Valve Closed (lbs. @ length) |

22 - 26 @ 1 21/32” |

|

Outer Valve Spring, Hydraulic Lifters - |

||

-Valve Open (lbs. @ length) |

96 - 104 @ 1 19/32” |

|

-Valve Closed (lbs. @ length) |

49 - 55 @ 1 15/16” |

|

Valve Lash - Series 40 Synchromesh NOTE: Does not apply to engines equipped with hydraulic valve lifters. |

||

Valve Lash at Road Operating Temp., Inlet and Exhaust - |

.015” |

--- |

Valve Lash using Shop Procedure |

.017”Go-.018”No Go |

--- |

Engine Oil System |

||

Pump Shaft to Bearing Clearance |

.0005" - .0020” |

|

Pump Idler Gear Bearing Clearance |

.001 - .0025” |

|

Pump Drive Gear Backlash |

.003" - .005” |

|

Pump Drive and Idler Gears Backlash |

.003 - .006” |

|

Pump Drive and Idler Gears End Clearance |

.003 - .006 |

|

Oil Pressure Valve Clearance in Body |

.003" - .006” |

|

Engine Cooling System |

||

Fan Belt Adjustment |

5/16” |

|

Fit of Bearing in Water Pump Body |

.0006T to .0009"L |

|

Pump Bearing Shaft Diameter |

5/8” |

5/8” |

Fan Hub Fit on Bearing Shaft |

.001"T - .0025"L |

|

Fan Hub Position on Bearing Shaft |

13/64" from end |

|

Radiator Hose Inside Diam. and Type |

1 9/16" Elbow |

|

Bypass Hose Inside Diameter |

3/4” |

|

Standard (151° ) Radiator Thermostat Calibration, @Atm. Press. - |

||

-Start to Leave Seat |

148° to 155° |

|

-Fully Open |

Not over 176° |

|

Standard (182° ) Radiator Thermostat Calibration, @Atm. Press. - |

||

-Start to Leave Seat |

178° to 185° |

|

-Fully Open |

Not over 211° |

|

Blue Print Specifications |

|||

248 |

263 |

320 |

|

Bore |

3 3/32”” |

3 3/16”” |

3 7/16”” |

Stroke |

4 1/8” |

4 1/8” |

4 5/16” |

Cylinder Head Volume |

98cc |

116cc |

|

Piston Dome Volume |

9.5cc |

14cc |

|

Deck Clearance |

.0012” - .0018” |

.0014” - .0020” |

|

Deck Height |

|||

Rod Length |

7.625" |

7.375" |

8.250" |

Rod/Stroke Ratio |

1.848" |

1.787" |

1.913" |

Bore/Stroke Ratio |

0.750" |

.773" |

.798" |

| 263 Bore pitch: cylinders #1-2, 3-4, 5-6, & 7-8 are 3.725" apart, cylinders #2-3, & 6-7 are 3.750" apart and cylinders #4-5 are 4.185" apart 320 Bore pitch: cylinders #1-2, 3-4, 5-6, & 7-8 are 4.075" apart, cylinders #2-3 & 6-7 are 4.290" apart, and cylinders #4-5 are 4.545" apart. |

|||