Heh, "in theory, there's no difference between theory and practice. In practice, there is."

I'd like to think that once bluebetty runs this to ground, she'll be able to do exactly that - post her experience: "Here's my problem, here's how I ended up solving it." The main issue - she's inherited someone

else's problem, no idea if they had a plan, or just started ordering and bolting up stuff and then found out it won't work. MAYBE they were happy with the 1" master, but something in the back (lines/hoses/cylinders/whatever) was bad and they capped it off rather than fix it. MAYBE they tried to run the back brakes but the pedal was too low to work. MAYBE they just never got a round tuit. That's probably the first thing to figure out, since it will set the stage for the rest of the changes.

What I've done with non-Buick (and specifically non-

55-Buick, which I've never seen in person!) brakes are

anecdotes, but they aren't

solutions...so hopefully once the

solution is found, then yeah, maybe a writeup would make sense.

Looks like one of the biggest challenges with updating the brakes on a manual-brake 55 Special is - the master cylinder on a 55 is a 3-bolt affair, most GM (and Ford) cars switched to 2-bolt flanges long ago, and finding a compatible 2-pot master with a 3-bolt flange is "challenging". And no idea if the stock master *is* too small for the brakes, and what alternatives there are if it is. Well, I can think of one right away - Wilwood makes smaller-piston calipers. But that's more $, too, and again, at this point it's just guessing (and increasing brake effort!) if that comes in to play.

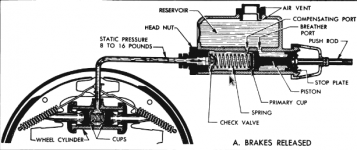

Stock 55 master:

@bluebetty

@bluebetty:

I can see 5 obvious choices to start with, in roughly increasing cost and/or difficulty:

1) continue to run the stock 1-lung master, figure out how to make it work. This is the one I'd probably personally start with,

assuming the pedal is high enough. You already have it, it already

seems to "work"...that's what I did on my '52. At least get it running/driving, and prove in the system. IF it works. And that way, if/when you decide to change it up later, you'll KNOW if you can run a 1" master, or if you'll need to make some sort of accommodation. You still may need to mess with residual pressure (unless the previous owner has already done that!), you may need proportioning valves or new rear cylinders...but it's the least-invasive.

Assuming it will work.

2) See if anyone has done anything obvious, like having a 2-bolt plate welded in where the 3-bolt mounting plate currently lives, or swapping around the mounting enough that it'll accept a more modern master cylinder. This one both scares and intrigues me...if you do it wrong, *bad things* would happen. And I doubt there's enough room (the 2-bolt flange looks visibly wider in pictures) to do this without more substantial surgery - but if there IS enough room, that would be a simpler exchange and would open up a lot of possibilities.

3) Figure out an adapter of some sort to adapt to a 2-bolt master without requiring the hackery of #2 - or figure some way to cobble a 4-bolt (Mopar-style) master to fit. That leaves the CAR intact.

4) see if anyone makes a 3-flange, 2-pot master that will work. C1 Corvettes seem to use a similar-LOOKING master cylinder, and there are apparently (probably horribly expensive, but still!) aftermarket 3-bolt masters that were available.

5) Or see if Wilwood or any of the other places you've contacted has a suggestion. Like swapping over to a boosted system. Or swapping the master to the firewall. That'd change *everything*. But then, you can do pretty much *anything*.

Anyone think of anything else?

Some junk I've spotted online, no idea of applicability:

The early Corvettes had 3-bolt flanges. The push rod is completely different, but...there are conversion kits for the early Corvettes to adapt to more modern master cylinders. A length of pipe with a 2-flange end on one side and a 3-flange end on the other. That'd move your master cylinder back so you'd need to make sure it'd fit, both length-wise *and* height-wise, and you'd need to fabricate your own (longer) pushrod, and you'd have to figure out how to fill it (Remote reservoir? New access hatch? Or would it "just work?")...but mechanically that looks

somewhat reasonable. I don't think the Buick would need that long of a tube. But you'd better REALLY trust your welder!

I've seen posts in some of the Corvette boards that you can drill new holes, and cut enough off, of a 4-bolt Mopar flange to make it fit a Corvette, so MAYBE the 55 Buick would be similar. I think the one pictured below is from like a 70 Roadrunner or Satellite. Apparently there's just enough metal there that you can make it work. And if you can believe the message boards, the Mopar ran external residual valves, so it MIGHT be hydraulically compatible out-of-the-box, once you get it to bolt up. But you'd still need some sort of method to seal the front of that from road grime, so that's more tweaking.

Or, you can look into a horribly-expensive, and probably really difficult to get parts for, custom Corvette master cylinder - like this one from ABS:

If online comments (I can find no specifications!) can be believed: It also supposedly has a 1" bore, so it should have the same pedal height as the stock cylinder, MIGHT bolt right into place, MIGHT be somewhat compatible. Obviously taking all of those posts with a grain of salt. Heck, we don't know for sure that the Corvette master cylinder will even bolt up!

And like I mentioned earlier, whichever way you go, you'd have to figure out how to devise some sort of means that'll let you retain a "bellows" for the pushrod - with the master under the floor, facing "backwards", you'll need to protect the face of the cylinder from road grime somehow. So again, starting from stock makes sense *to me*, but it still needs to be proven if even a possibility.

Or, following through on #5, you just swap the whole thing out. Run a boosted system. Or: Moving the master to the firewall, while changing *everything*, would...change *everything*, and that opens up *every* possibility.

This kinda goes with the territory. You're taking a somewhat-unique car and making it do something that it's never done. And unless someone has done it themselves, or at least has a 55 to

look at, it's all guesswork.