exchaoordo

Member

Please help me understand and wire up my kickdown solenoid

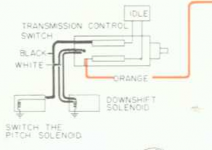

I think I want to wire a white/black down to the transmission, but I don't understand where that would get power from. I don't understand the wiring diagram that shows the Switch Pitch & Downshift solenoid. Here's some details and a few pics. There is a t-shaped connector at the transmission and pigtails coming from the solenoid: one pair white (or very faded yellow)/black; the other pair is twin grays. At the joint in the throttle rod there is a switch that appears to have been wired to the solenoid.

I think I want to wire a white/black down to the transmission, but I don't understand where that would get power from. I don't understand the wiring diagram that shows the Switch Pitch & Downshift solenoid. Here's some details and a few pics. There is a t-shaped connector at the transmission and pigtails coming from the solenoid: one pair white (or very faded yellow)/black; the other pair is twin grays. At the joint in the throttle rod there is a switch that appears to have been wired to the solenoid.