You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1950 Roadmaster steering effort

- Thread starter CALLBALD

- Start date

Easiest way is to locate & install P/S from a '52 Roadmaster.

Also read about where someone installed electric P/S in an older car, seem to remember, Buick??? to the shaft under the dash.

I know it was a Motors magazine many years ago, probably 10-15 years.

Tom T.

Also read about where someone installed electric P/S in an older car, seem to remember, Buick??? to the shaft under the dash.

I know it was a Motors magazine many years ago, probably 10-15 years.

Tom T.

mgaugustine

Member

I am also interested in installing a power steering set up from a later 320 CID Roadmaster. It isn't so easy to find a complete system for that. I am sure I can, that isn't the issue... but has anybody done this in recent history that can say if the appropriate seals and other age-dependent things are still available? I suspect that after seventy years the seals would probably leak like a sieve. Especially off of any parts car that I might find.

So... does anybody know if parts to rebuild one are still available out there?

So... does anybody know if parts to rebuild one are still available out there?

I did one20 years ago, and everything I needed was available. The only interesting thing was there was 5 springs in the the valve body? and two were broken. I took a couple to a spring shop and they wound me a new set very reasonable. The steering works great today. It was a 1952 setup.

50 bucktooth

Member

I've been wanting to outfit with my 50 with power steering as well. An issue with going to electric steering is that it requires a changeover to a 12 volt system something I'd rather not do at this time as my 6v wiring is fine.

I've inquired, and 6v electric p/s systems just don't exist. Additionally, if replacing a 6v system with 12, you'll lose the "foot start" option, as the electrics on the carb are geared to 6v (there may be some electrical work around, but I'm not familiar with it). You could (as many do who convert to 12v) simply install a starter push button on the dash, but you lose the uniqueness of starting an older Buick.

In the meantime, I've installed a set of Cocker "American Classic bias look radials" 7.60 x15 wide white walls, running @ 35psi. They are quite narrow compared to the Diamondback radials (225-75r15) I had previously. (see photos below)

The narrower footprint reduces turning effort. At speed, it's quite low and very reasonable, but during parking it is still a bit heavy, but manageable -- nothing like the heft needed for the Diamondbacks....hope this helps.

David in Santa Cruz

BTW, if anyone has any leads on a complete '52 power steering setup, I'd be interested too.

I've inquired, and 6v electric p/s systems just don't exist. Additionally, if replacing a 6v system with 12, you'll lose the "foot start" option, as the electrics on the carb are geared to 6v (there may be some electrical work around, but I'm not familiar with it). You could (as many do who convert to 12v) simply install a starter push button on the dash, but you lose the uniqueness of starting an older Buick.

In the meantime, I've installed a set of Cocker "American Classic bias look radials" 7.60 x15 wide white walls, running @ 35psi. They are quite narrow compared to the Diamondback radials (225-75r15) I had previously. (see photos below)

The narrower footprint reduces turning effort. At speed, it's quite low and very reasonable, but during parking it is still a bit heavy, but manageable -- nothing like the heft needed for the Diamondbacks....hope this helps.

David in Santa Cruz

BTW, if anyone has any leads on a complete '52 power steering setup, I'd be interested too.

Last edited:

mgaugustine

Member

Thanks for the input. I know I am not the only one who has talked about this, I have a close friend who is eighty two years of age and has wanted to do this conversion for at least thirty of the last years. At his age now, it has become a real issue to steer his 1941 Roadmaster... which he has been driving since 1958! Now I find myself wanting power steering on my own early Roadmaster. (I'm considerably younger than he is, but still old enough to see the plus side of power steering as I age.) Thanks again.I did one20 years ago, and everything I needed was available. The only interesting thing was there was 5 springs in the the valve body? and two were broken. I took a couple to a spring shop and they wound me a new set very reasonable. The steering works great today. It was a 1952 setup.

50 bucktooth

Member

I have little electrical engineering knowledge, so maybe someone who knows can chime in:

1. Appears no one makes 6v electric p/s motors.....perhaps there is a source for some special application I'm not aware of... ie farm equipment, aircraft, boat, industrial?

2. Could a 12v electric p/s motor be converted to 6v?

3. 12v to 6v reducer power converter kits do exist for motorcycle accessory applications (see link below), but I suspect they are not robust enough for the current load demands of a p/s unit.

4. One article states typical electric p/s unit demands are as follows: 30-40 amp during normal turning, 15-20 steady state, 80-100 at full lock. You'd need a substantial generator for that sustained output....or an aftermarket alternator.

Further discussion welcomed....doing curls may be the only alternative

chpmotorsports.com

chpmotorsports.com

-

1. Appears no one makes 6v electric p/s motors.....perhaps there is a source for some special application I'm not aware of... ie farm equipment, aircraft, boat, industrial?

2. Could a 12v electric p/s motor be converted to 6v?

3. 12v to 6v reducer power converter kits do exist for motorcycle accessory applications (see link below), but I suspect they are not robust enough for the current load demands of a p/s unit.

4. One article states typical electric p/s unit demands are as follows: 30-40 amp during normal turning, 15-20 steady state, 80-100 at full lock. You'd need a substantial generator for that sustained output....or an aftermarket alternator.

Further discussion welcomed....doing curls may be the only alternative

Conversion kit for, 12 Volt CDI motor to 6 Volt – CHP Motorsports

chpmotorsports.com

chpmotorsports.com

-

30-40 amps during normal turning can be handled by a generator. How long are you going to hold it at full lock anyway?? A moment at most??

Swapping over to 12 volts is mostly a no brainer. The 6v wiring is more than capable of handling 12 volts as it is a heavier gauge to begin with.

You will have to swap things out like the blower motor. Just get a specs catalog & start comparing. I've done this quit a bit at my shop in the past. No big deal.

No need to change fuses as all they are doing is measuring amperage & 12v requires LESS amperage.

You will need a power converter for the radio or just send it out for a refresh/update. Again, no big deal.

No problem with the fuel gage as it only reads resistance, NOT voltage.

AND there's more, I just don't have the time to write it all down.

Do some more research on the subject & I'm sure you'll be surprised how easy it can be.

Goodnight,

Tom T.

Swapping over to 12 volts is mostly a no brainer. The 6v wiring is more than capable of handling 12 volts as it is a heavier gauge to begin with.

You will have to swap things out like the blower motor. Just get a specs catalog & start comparing. I've done this quit a bit at my shop in the past. No big deal.

No need to change fuses as all they are doing is measuring amperage & 12v requires LESS amperage.

You will need a power converter for the radio or just send it out for a refresh/update. Again, no big deal.

No problem with the fuel gage as it only reads resistance, NOT voltage.

AND there's more, I just don't have the time to write it all down.

Do some more research on the subject & I'm sure you'll be surprised how easy it can be.

Goodnight,

Tom T.

suntreemcanic

Experienced Member

I have a 52 Buick and I changed to 12 volts years ago and I retained my foot start option. The switch on the carburetor does't care whether it is 6 or 12 volts. If you are looking to put power steering on your Buick be aware you must also change the steering column. So a Super power steering unit probably will not work on a Roadmaster. As I understand the power steering option was only available on Dynaflow cars. I believe the hardest parts to replace will be the hoses because the fittings are SAE threads.

50 bucktooth

Member

What needs to be done to retain the foot activated starter action?....not the starter itself, but the switch on the side of the Stromberg....will 12 fry the contacts?

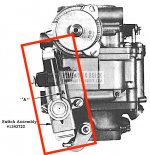

Keeping that unique feature is important to me...don't want to replace it with a button, as many do.....previous owner installed a button...I replaced the carb switch to restore the originality. See below.

Keeping that unique feature is important to me...don't want to replace it with a button, as many do.....previous owner installed a button...I replaced the carb switch to restore the originality. See below.

Attachments

suntreemcanic

Experienced Member

No the 12 volts will not hurt the switch. I drove mine for over 70,000 miles and it still worked perfect. You do not have to change the starter. A 6 volt starter will last forever, the 12 volts turns the engine over a lot faster and the engine starts easier. You will need to change the starter solenoid and the starter relay on the firewall.

50 bucktooth

Member

Based on all of your responses.....I may have to start my Christmas shopping early....

50 bucktooth

Member

tires@35psi....waist@34"

See what the MAX pressure is stated on the side of the tire & stay a few pounds under.

I have 12 volt mini starters for the straight eights IF needed.

MANY shops make hydraulic hoses in ANY configuration needed so NOT a big deal.

Tom T.

I have 12 volt mini starters for the straight eights IF needed.

MANY shops make hydraulic hoses in ANY configuration needed so NOT a big deal.

Tom T.

firstofeight

Experienced Member

See what the MAX pressure is stated on the side of the tire & stay a few pounds under.

I have 12 volt mini starters for the straight eights IF needed.

MANY shops make hydraulic hoses in ANY configuration needed so NOT a big deal.

Tom T.

AND the starters work really well.

Ben

mgaugustine

Member

Sure, but this is a two year old post now. Instead of being eighty two... he will be eighty four years young this week. Not so bad on the road, but tight parking spaces are another matter.

Usually in automobile diagnostics is to keep it simple. Inspect steering geometry, check steering gear box if worn, caster, toe, worn steering parts, tire pressures, anything that may cause hard steering. The steering gear has ball bearings in the worm gear, you can get those replaced at time of "if" needed to be rebuilt.

The caster places a role in the steering effort. It calls for 50 Buick 3/4 degrees positive with both sides to be within 1/2 degree. The allowable range is 1/4 to 1 1/2 degrees. Caster in the lower to negative numbers will make it easier to steer. So if your caster is 1/1/2 degrees it would fall with in spec, but it would be harder to steer. I would move the Caster to its minimum allowable spec of 1/4 degrees, test drive it and make an assessment.

The caster places a role in the steering effort. It calls for 50 Buick 3/4 degrees positive with both sides to be within 1/2 degree. The allowable range is 1/4 to 1 1/2 degrees. Caster in the lower to negative numbers will make it easier to steer. So if your caster is 1/1/2 degrees it would fall with in spec, but it would be harder to steer. I would move the Caster to its minimum allowable spec of 1/4 degrees, test drive it and make an assessment.

Last edited: